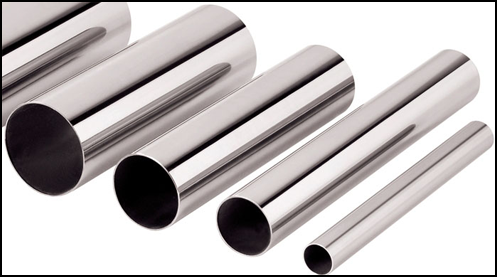

Products

Longitudinally, Welding Process High Frequency Induction Welding (HFI). Raw Material cold and hot rolled steel coil in accordance with required quality.

Diameter : 15 - 323.9 mm

Wall Thickness : 2 - 12 mm

Tube Length : 6 m (up 12 m upon request)

Mill Test Certificate : According to 10204 2.1 or 2.2 or 3.1 or 3.2

All the required tests and inspections are carried out in compliance with the customer requirements and related standards by using modern inspection and testing equipments.

* All tests required by API 5L standard are applied to the natural gas pipes.

* Manufactured from special quality steel bands.

* Ultrasonic and nondestructive tests are used.

* The physical, chemical and mechanical tests

* All pipes pass from 100% hydrostatic pressure test and the magnetic tests and controlled whether they leak or there is a fault in the metallographic structure of the pipe or not.

You can find three different production groups as ERW LONGITUDINALLY as below :

Industrial Pipes, Hollow SectionAutomotive industry, Furniture industry, Construction, Light and heavy duty machinery.

Production Standart : EN 10305-5 ** DIN 2458 , 1615 ** BS 6363 ** ASTM A500 ** EN 10219

Material

: EN 10025: S 235, S 275, S 355

API 5L: Gr A, B, X42, X52, X60, X65

Production Standard : EN 10217-1

** EN 10255 ** DIN 1626 ** DIN 2440-2441

** DIN 1626 ** ASTM A-53

NFA 49-145

** UNI 8863 **

BS 1387 (Medium and Heavy) ** ISO 65 (Light Series I and II)

Material : EN 10025 : S 235 JR, S275 JR, S355 JR

API 5L : Gr A, B,

X42

Outside Surface : Black, oil, black varnish, Epoxy - AWWA C210 ** 3 layer PE coating - DIN 30670 ** Galvanizing

Hot Dip Galvanizing :

The galvanized pipes has NSF certificate which approve these pipes can be used

inpotable water systems

EN 10240 ** EN ISO 1461 (BS 729) ** ASTM A-53

** A-90 ** NFA 49-700 **

UNI 5745

The oil pipes are used in the transportation of oil, fuel-oil, oil, natural gas and chemical liquid. All pipes pass from 100% hydrostatic pressure test and the magnetic tests and controlled whether they leak or there is a fault in the metallographic structure of the pipe or not. Some pipes supply with heat treatment.

Pipe Production Standards and Material:

EN 10208 - 2 : L 245 MB, L 290 MB, L 245 MB, L 360 MB, L 415 MB, L 450 MB

API 5L : API 5L Gr A, B, X42, X52, X60, X65

Outside Surface : Black, Oil, Black Varnish ** Epoxy (AWWA C210) ** 3 layer PE coating - DIN 30670

Inside lining : Black ** Epoxy (AWWA C210)